Canadian Sales Representative

Careers

with PlantTapeCanadian Sales Representative

Our Company:

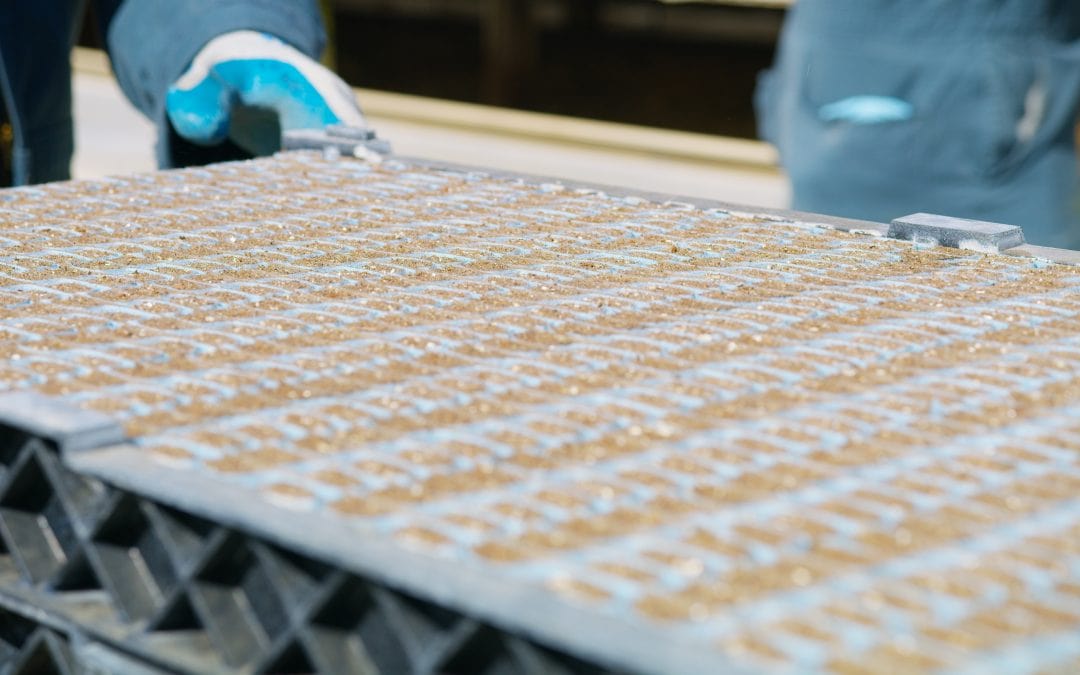

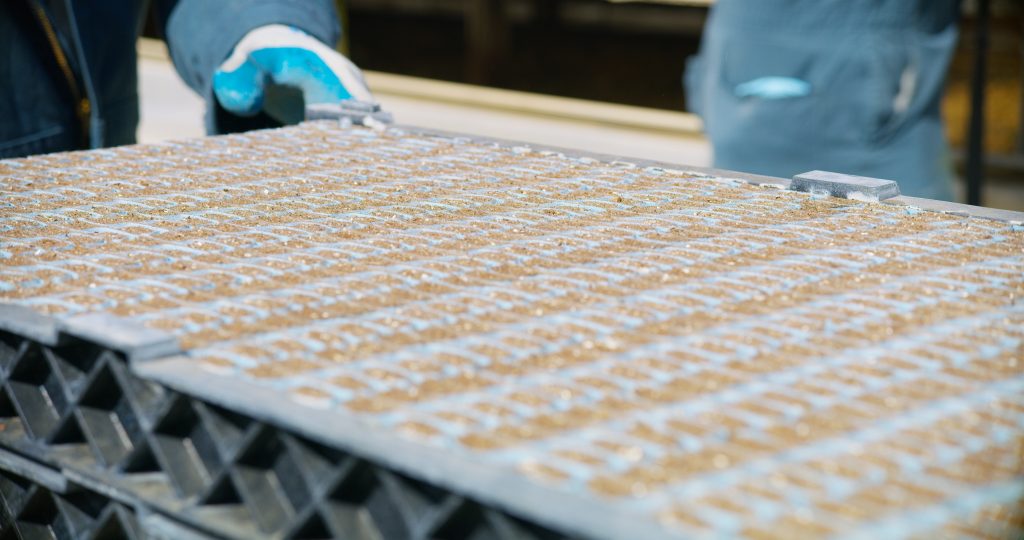

PlantTape is an automated transplanting system aimed at reducing costs and labor for growers. The PlantTape process is built around tape that holds seeds and seedlings. The tape facilitates ease of sowing, efficient nursery operations and automated transplanting. With one of the most progressive automated transplanters on the market, PlantTape now has over 100 machines operating globally and 1 billion plugs sold annually.

Location: Ontario or Quebec, Canada

The Role:

The Canadian Sales Representative will be responsible for ensuring success with the PlantTape Automated Transplanting System with current accounts and new business opportunities. Using your agricultural prowess you will be tasked with building and maintaining long-term business relationships through a “boots on the ground” mentality. A successful candidate will be self-motivated, disciplined and eager to learn.

Salary Range: $65,000 – $70,000 per year

Areas of Responsibility:

- Frequent attendance to current accounts’ plantings to ensure quality and successful operation of the PlantTape system

- Work closely with nursery partners to grow volume and ensure quality of product

- Work with East Territory Manager to create, implement and maintain a territory sales plan; complete with obtainable goals and deliverables

- Track and communicate all customer activities to the East Territory Manager and PlantTape leadership

- Work closely with the equipment department to ensure excellent customer support and service by reporting and personally resolving any equipment troubleshooting events

- Responsible for PlantTape equipment set up and training with new clients and demonstrations

- Troubleshoot any machine issues with current accounts or demonstrations by using your comprehensive knowledge of the PlantTape system

- Participate and contribute in weekly sales meetings

- Coordinate and help organize trials and equipment demonstrations, working closely with the East Coast Territory Manager.

- Attend relevant sales events, such as tradeshows

Preferred Qualifications:

- Bachelor’s Degree in ag-business or related field (preferred)

- 1-3 years of experience in agricultural sales. (Seed, equipment, Ag tech, irrigation, fertilizer etc.)

- Knowledge of electrical, hydraulic and mechanical systems

- Fluent in English and French (preferred)

- Strong knowledge and understanding of Canadian produce industry

- Excellent organizational skills, attention to detail and ability to multi-task in a fast paced environment

- Self-motivated

- Ability to prioritize while handling multiple tasks

- Valid driver’s license

- Ability to travel internationally (valid passport)

- Must be able to lift 50 lbs.

- Afterhours and weekend work may be required

- Work in an outdoor and indoor environment around moving parts and equipment.

Physical Demands

- Extensive travel around Canada and occasional travel to Northeast and Midwest

- Bi-yearly trips to Salinas, California

Apply Here:

Recent Comments